Contract Machining

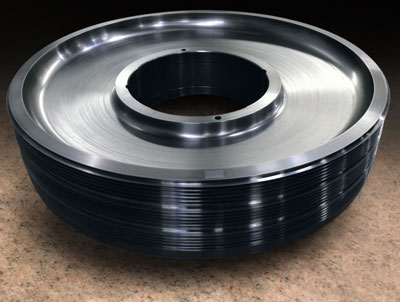

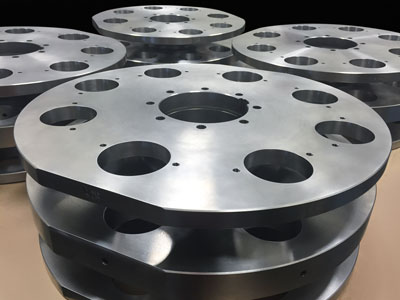

Milwaukee Bearing & Machining Inc. has the equipment and experience needed for precision Vertical CNC Machining from 1" to 99" in diameter. With our various CNC machines, manual milling machines, saws, grinders and more, you can rest assured that we can produce your part to your exact specifications. Each part goes through our quality assurance process to ensure high quality workmanship goes into each order.

Milwaukee Bearing & Machining Inc. has the equipment and experience needed for precision Vertical CNC Machining from 1" to 99" in diameter. With our various CNC machines, manual milling machines, saws, grinders and more, you can rest assured that we can produce your part to your exact specifications. Each part goes through our quality assurance process to ensure high quality workmanship goes into each order.

We specialize in Vertical CNC Machining Services, including:

- Turning

- Splitting

- Milling

- Drilling

You can count on us to use the right tools and equipment to manufacture the precise components you order. We have the CNC machine programming expertise to be efficient and cost effective when producing your precision metal product, even for the very first time! Our past parts list includes various seals, damper spiders, diffuser inlets, compressor impellers, and more. Browse our Machined Parts portfolio to view some of our past projects and contact us today to discuss how we can fulfill your part manufacturing needs.

Machine List

Each piece of machinery that we have is essential to our company. With our high-tech equipment, our customers can be guaranteed precise bearings and other machined parts at their exact specifications. Below is the vast list of equipment that our experts use to manufacture your high-quality contract machined parts.

CNC Vertical Machining Centers

A type of Computer Numerical Control (CNC) machine that is highly automated and multi-functional. Its vertically oriented spindles approach the workpiece, which is mounted on a worktable, from above and are equipped with a tool magazine system and automatic tool changer.

- 2x Hurco BMC-50/50 Vertical Machining Center

- Haas VF4 Vertical Machining Center

- Johnford DMC-2600SH Vertical Milling Center

- 2x Haas VF0 Vertical Machining Center

- Hass UMC 1000 S Axis

- 3x Haas VF3 Vertical Machining Center

CNC Horizontal Bars

- Toshiba BTD-110.R16 CNC Horizontal Bar

- Toshiba BTD-200QF CNC Horizontal Bar

- 2x Johnford BMC-110 CNC Horizontal Bar

CNC Turning Centers

Advanced computer numerically controlled (CNC) machines. They can have 3-5 axes, with a multitude of cutting capabilities, including milling, drilling, tapping, and, of course, turning.

- Hass ST-30 Lathe

- Daewoo Puma 10HC Turning Center

- Daewoo Puma 12S Turning Center

- Haas SL-30 Turning Center

- 2x Haas SL-30 Turning Center

- 2x Topper Tong Tai TNL-130 AL

- Hass ST-35Y Live Tool Lathe

CNC Vertical Turning Lathe

Our large, ram-type machines ideal for heavy-duty and high-power cutting of medium and large parts.

- Toshiba TUE 20 CNC Vertical Boring Mill - Live Tooling

- 2x Youji YV-800A CNC Vertical Boring Mill

- Youji VTL-2000 ATC

- Youji VTL, YV-1600 ATC+C

- 2x Toshiba TUE 20 CNC Vertical Boring Mill

- 2x Youji YV-1000ATC CNC Vertical Boring Mill

- 3x Toshiba TUE 15 CNC Vertical Boring Mill

Manual Milling Machines

Used for machining a flat, curved or unusual surface by putting a piece of material against a rotating cutter, with cutting edges. The motor-driven spindle mounts and revolves the milling cutter, and a reciprocating adjustable worktable mounts and feeds the workpiece.

- Mitts and Merrill Keyseater

Manual Turning Machines

The process in which a cutting tool shapes a workpiece while it moves. It needs a constant operator to supervise the lathe.

- Clausing Model 5914 Engine Lathe

Saws

Our machinery equipped with saws are used for cutting the correct amount of material for each part. The cutting tools of sawing machines may be thin metallic disks with teeth on their edges, thin metal blades or flexible bands with teeth on one edge, or thin grinding wheels.

- 2x Marvel Series 8 Mark 1 Band Saw

- Doall Model C-70 Band Saw

Grinders

Our grinding machines are equipped with an abrasive wheel used for producing fine finishes or making light cuts on metals and other materials.

- BSA Churchill Model NB Surface Grinder

- Cincinnati Universal Cutter Grinder

- Karstens O.D. Grinder Model 16A

Miscellaneous

We also have other advanced equipment and machinery to develop and test the quality of our products to ensure durable, reliable, and efficient parts are produced by Milwaukee Bearing and Machining Inc.

- Unitek Tap Disintegrator

- Chalmers Testing Equipment (to check babbitt bond strength)

- Bearing Crush Height Validator

- Setco Spark Erosion Grinder (For Grinding Honeycomb Seal Material)

Centrifugal Babbitt Casting Equipment

- Centrifugal Casting Machine CB-45-45-WC

- 2x German Spinners 30”

Contract Machining Projects and Resources

- Siemens Energy Static Seal Project - When Siemens Energy came to us with a custom static seal design, we were up to the challenge. Our team followed their blueprints to manufacture the highly customized piece that combined multiple smaller parts.

- Vertical CNC Machining - Our vertical CNC machining is run by our highly experienced team to ensure precision and close tolerances with various vertical machining centers and turning lathes or boring mills.

- Outsourcing CNC Machining - We understand the importance of producing a part based on your exact specifications and we have the right equipment to produce the high quality parts that your company requires.